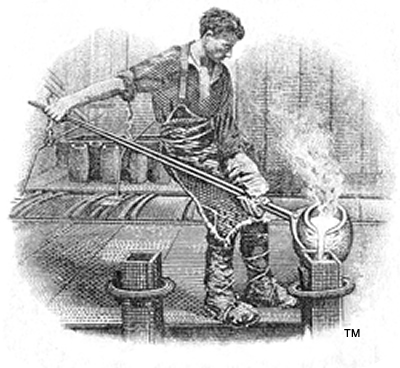

Crucible Legacy Crucible has been making specialty steel in Syracuse continuously since 1876. Founded on a tradition of metallurgical expertise and technological innovation, Crucible has been granted more than 1,000 patents throughout its history. With a reputation for the highest-quality products, Crucible has maintained its position as a market leader, even in today’s competitive business climate. Sheffield Origins Crucible’s roots can be traced to 1776, when Naylor and Sanderson Steel Mill was established in Sheffield, England, to produce fine-quality tool steel using the crucible method. During the 1800s, the company-then known as Sanderson Brothers-exported increasing quantities of tool steel to America, and decided to establish a steelmaking plant in Syracuse because of the city’s proximity to major U.S, transportation lines, including the Erie Canal and the New York Central Railroad. In 1876, Sanderson purchased Sweet Iron Works and established Sanderson Brothers Steel Company. The Crucible Method of Steelmaking  In 1883, Sanderson Brothers Steel Company built a new gas-fired crucible melting furnace. This high-temperature furnace held up to 30 graphite pots, called crucibles, each charged with 60 to 100 pounds of iron plus selected alloy additions. Once the metal charge became molten at 3,000 degrees Fahrenheit, each crucible was then lifted from the furnace with long-handled tongs, and the liquid steel was poured, or “teemed” into individual ingot molds. The crucible method, though labor intensive, produced the highest-quality tool steels available at the time. Working in the melt shop was tough, hot work. The pourer, or “teemer” often wrapped his legs in wool and burlap and thoroughly soaked them with cold water as protection from the intense heat. |